2012

7th August

Lynjoon founded in 2012

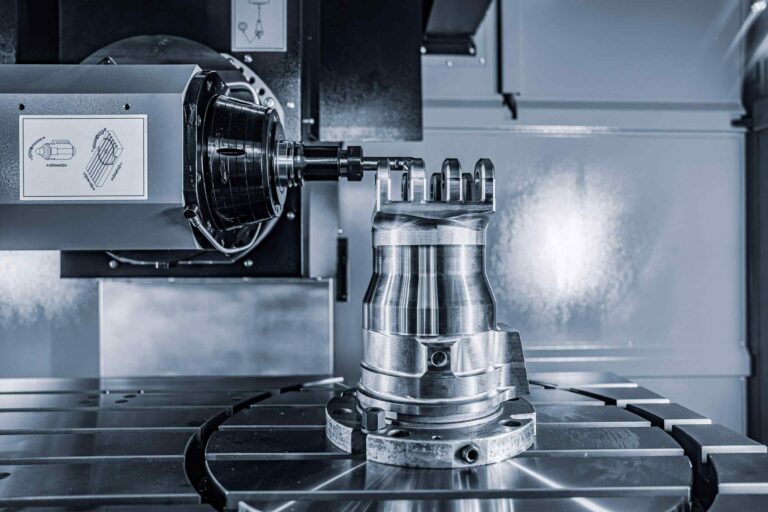

In 2012, we began building our own machining production line, objectively innovating and enabling the manufacturing of products, while simultaneously developing a parallel platform. We fully controlled scalable testing processes to ensure a reliable supply chain. This significantly elevated our performance to the top level.

11th November

First 10 Employees

The founding team consists of engineers and entrepreneurs with many years of experience in machining and automation equipment R&D. Initially, the company primarily focused on precision mechanical parts processing and the manufacturing of basic automation equipment. Since then, “LYNJOON” has become a rising star in Shenzhen’s automation manufacturing sector.

December 1, 2015

Technological breakthrough

The company’s R&D team has successfully launched several proprietary-brand automated production line modules, automated assembly equipment, and intelligent testing equipment. These products are used in: Automotive parts production line automation; Precision assembly of medical devices; Automated assembly and testing of consumer electronics.

Lynjoon’s equipment is gradually entering manufacturing-intensive regions such as Guangdong, East China, and Central China, and has initially established cooperative relationships with dozens of leading companies in the industry.

Achievements include: becoming the annual designated supplier for several OEM/ODM companies; having R&D results incorporated into draft industry standards; and the technical team participating in the National Automation Expo for the first time and winning professional awards.

2016

March

Industrial ecosystem construction

As its business expands, Lynjoon has entered a critical period of branding and ecosystem development.

Strategic Brand Repositioning

The company has officially positioned itself as a “Provider of Integrated Intelligent Manufacturing Solutions,” not merely an equipment manufacturer, but a driver of production efficiency and intelligent manufacturing transformation.

Standardization and Quality System Construction

Lynjoon has introduced an international quality management system, completed ISO9001 full-process system certification, and passed multiple industry product certifications, enhancing the competitiveness of its products in the global market.

May

Expanding Overseas Markets

The company’s products have begun to be exported to North America and parts of Europe, becoming an important link in China’s manufacturing industry’s integration into the global supply chain.

2022

June

Digital Transformation and Product Intelligence

Entering the “Digital Era,” Lynjoon fully launched its Intelligent Manufacturing Upgrade Strategy:

Independent R&D of Intelligent Control Systems

Introducing a top-tier industry control architecture, launching an integrated intelligent assembly and monitoring system based on PLC + visual AI + IoT feedback mechanisms.

Cooperation with Universities and Research Institutions

Establishing joint laboratories with key domestic universities to promote the R&D of intelligent collaborative robots (Cobots) and automatic visual inspection technologies.

Digital Factory Implementation

Establishing a demonstrative digital intelligent factory at its Shenzhen headquarters, realizing the entire process from order receipt → production scheduling → equipment collaboration → intelligent quality inspection → data feedback.

2025

February

Towards a Global Leader in Industrial Automation

Looking ahead, Shenzhen Lynjoon Automation Co., Ltd. will continue to make breakthroughs in the following strategic directions: Global deployment, establishing technical support and service centers in Europe, North America, and Southeast Asia to accelerate global market penetration.

Promoting the industrialization of core technologies, including:

Intelligent assembly robots;

Autonomous learning vision inspection modules;

Fully autonomous scheduling production execution systems (MES + AI optimization layer).

August

Globalization and Ecosystem Building

Cross-industry Collaborative Ecosystem

Building an open platform and establishing industry alliances with manufacturers of industrial software, machine vision, and automated actuators to create an automation ecosystem cluster for China’s high-end manufacturing industry.

The ultimate goal is to become “one of the benchmark enterprises in China’s automation industry,” leading the manufacturing industry into a new era of greater efficiency, intelligence, and greener practices.

A team of highly skilled manufacturers, prepared to meet any request for fabrication, tool crafting or product design and production.

A team of highly skilled manufacturers, prepared to meet any request for fabrication, tool crafting or product design and production.

People tell it the bestQuotes

The sample has been received and itlooks spectacular! In particularthesurface finishing is very nice and thefinished piece feelswonderful in hand.We are very please with the result ofyourwork.

Michael Wright

Bello Servicing

We did a quick build test of all versionsand the looks, performancespecs andfunctionality were good, and theyworked just as well, asalways. Deliverydate no problem!

Daniel Huberth

Applauz

We placed our first order of 1500stainless steel parts from Lynjoon andallparts of the sample were great,assembled correctly and we areveryhappy with the material and finish.

John Strength

Avantage

I am very satisfied with the products.

One product was a bit tricky, and l had toraise some questions before work couldcontinue, but ultimately there were nodelays. Lynjoon’s delivery speed seemsto be faster than any other company inthe UK.

Mia McBride

Estato

The file upload process is intuitive andconvenient. Delivery times and pricingoptions are also plentiful. The product lreceived exceeded my expectations, andI will definitely choose Lynjoon again forfuture projects.

John Fox

Codiqa

Lynjoon’s website is very user-friendly,and they offer many manufacturingoptions. The parts are of high quality andwell-packaged. Delivery is faster, and theprices are reasonable.

Hollie Neal

Nifty

While delving into innovative thinkingLynjoon also keeps a close eye on coreobjectives to achieve leapfrogintegration.

Elsie Moore

Konstrakt