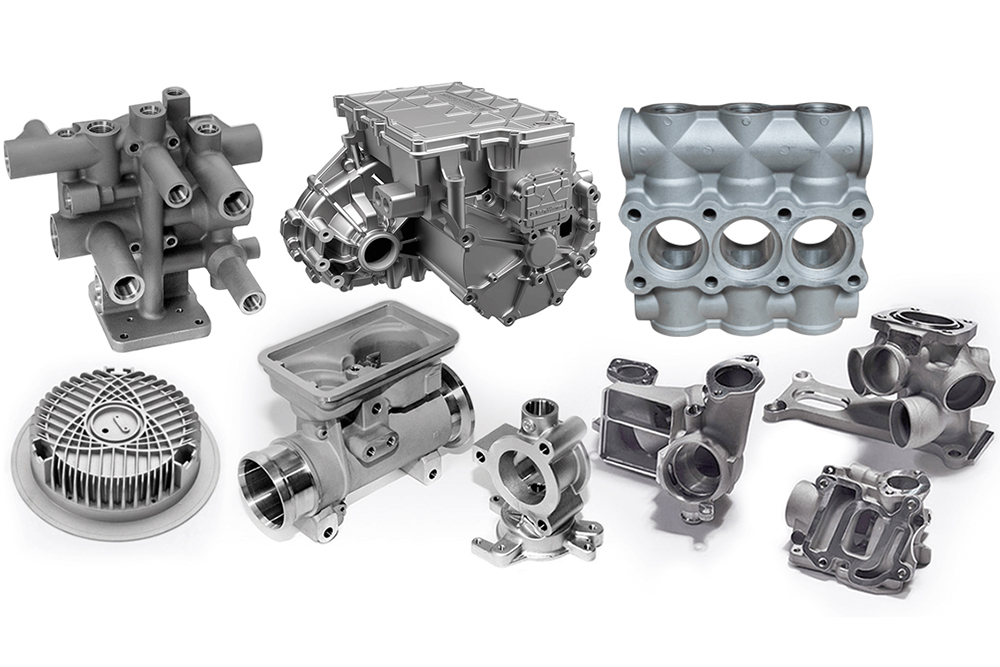

High-efficiency die casting metal forming solution: one-time molding of complex structures with high precision and high consistency.

- High-pressure, high-speed filling enables one-time molding of complex structures.

- High dimensional accuracy and excellent surface quality.

- Suitable for stable medium- to large-volume production.

- Significantly reduces unit manufacturing costs.

What is Die Casting?

Die casting is a metal forming process in which molten metal is forced into a precision metal mold under high pressure and high speed, and then rapidly cooled to its final shape.

This process is renowned for its high production efficiency, high dimensional accuracy, and excellent surface quality, making it particularly suitable for manufacturing complex, thin-walled metal parts for mass production.

Die casting is widely used in the automotive, electronics, and industrial equipment industries, and is an indispensable key process in modern manufacturing.

Our Die Casting Manufacturing Capabilities

- Applicable Materials: Aluminum Alloy / Zinc Alloy / Magnesium Alloy

- Equipment Tonnage: 200T – 9000T Die Casting Machine

- Single Piece Weight: 300g – 200kg

- Dimensional Accuracy: CT5 – CT7

- Production Mode: Medium to Large Batch Continuous Production

Why Choose Die Casting?

1️⃣ One-Step Molding of Complex Structures

It allows for the creation of complex structures such as thin walls, deep cavities, and ribs, significantly reducing subsequent assembly.

2️⃣ High Dimensional Accuracy and Consistency

The metal molds offer high stability, ensuring excellent dimensional repeatability for batch production.

3️⃣ Excellent Surface Quality

The castings have a smooth surface, suitable for direct painting, electroplating, or anodizing.

4️⃣ High Production Efficiency

Short molding cycle time, suitable for mass production, significantly reducing unit cost.